What's the Difference Between PSI, PSIA, and PSIG?

Whether they’re venturing into the next county or hauling a load halfway across the country, every commercial truck driver knows to check their tire pressure before starting each day. (Fortunately, most also know not to use a small bat or hammer to do it anymore!)

After all, under-inflated tires can lead to increased wear, higher fuel consumption, and poor handling, while overinflated tires can cause reduced traction, bad braking, and a generally rough ride.

In other words, maintaining the right truck tire pressure isn't just about avoiding a blowout or flat–it's about staying safe on the road, maximizing fuel efficiency, and improving the vehicle's longevity and performance.

So it’s important to find that sweet spot, and not just for drivers–repair and maintenance professionals can benefit from understanding the basics of pressure measurements, too, whether it’s for tires, brakes, or other components on a medium- or heavy-duty truck.

“OK, that’s straightforward enough,” you may be thinking. Well, buckle up…because the ride’s about to get a little bumpier thanks to a familiar acronym and its lesser known, but still very important, cousins.

Understanding Tire Pressure (PSI)

When we think about pressure, the term that often comes to mind is PSI, or pounds per square inch. And for good reason, since PSI is the standard unit of pressure measurement in the US. It’s used on everything from footballs to commercial semi tractor trailer tires. But what is PSI exactly?

Without sounding like 7th period science class, PSI is the pressure you get when one pound of force is applied to one square inch of area. How does that apply to our world? When you inflate a tire, air molecules spread out and put pressure on the inside of that tire. PSI tells you how much force is exerted on the tire per square inch of its surface. The more air you add, the greater your PSI (since the surface area inside the tire stays the same).

Whether you’re on the service side or a CDL driver yourself, a solid grasp of air pressure units goes a long way toward ensuring trucks’ safety and reliability on the road.

Delving Deeper: PSIA vs. PSIG

Here’s where the “fun” starts: Our first variation is called PSIA, which stands for pounds per square inch absolute. But what is PSIA? It’s basically the pressure measured in a vacuum, also known as pressure relative to zero.

This measurement takes into account the atmospheric pressure at sea level, which is approximately 14.7 PSI. When using PSIA to measure tire pressure, you’re essentially measuring the total pressure inside the tire, including the atmospheric pressure. So a tire with no air in it would have a PSIA of 0.

Our second variation, called PSIG, means pounds per square inch gauge. This measurement includes the pressure from the weight of the atmosphere. That means when you see a tire pressure reading in PSIG, it’s telling you how much pressure is being exerted on the tire beyond the atmospheric pressure.

To put it another way, PSIG takes atmospheric pressure–the pressure outside the tire–into account in its measurement, whereas PSIA does not. So at sea level, 0 PSIG is equal to 14.7 PSIA, and 0 PSIA equals -14.7 PSIG.

For quick reference, here’s a simple formula (shown two ways) for converting between PSIA and PSIG:

PSIA = PSIG + atmospheric pressure / PSIG = PSIA - atmospheric pressure

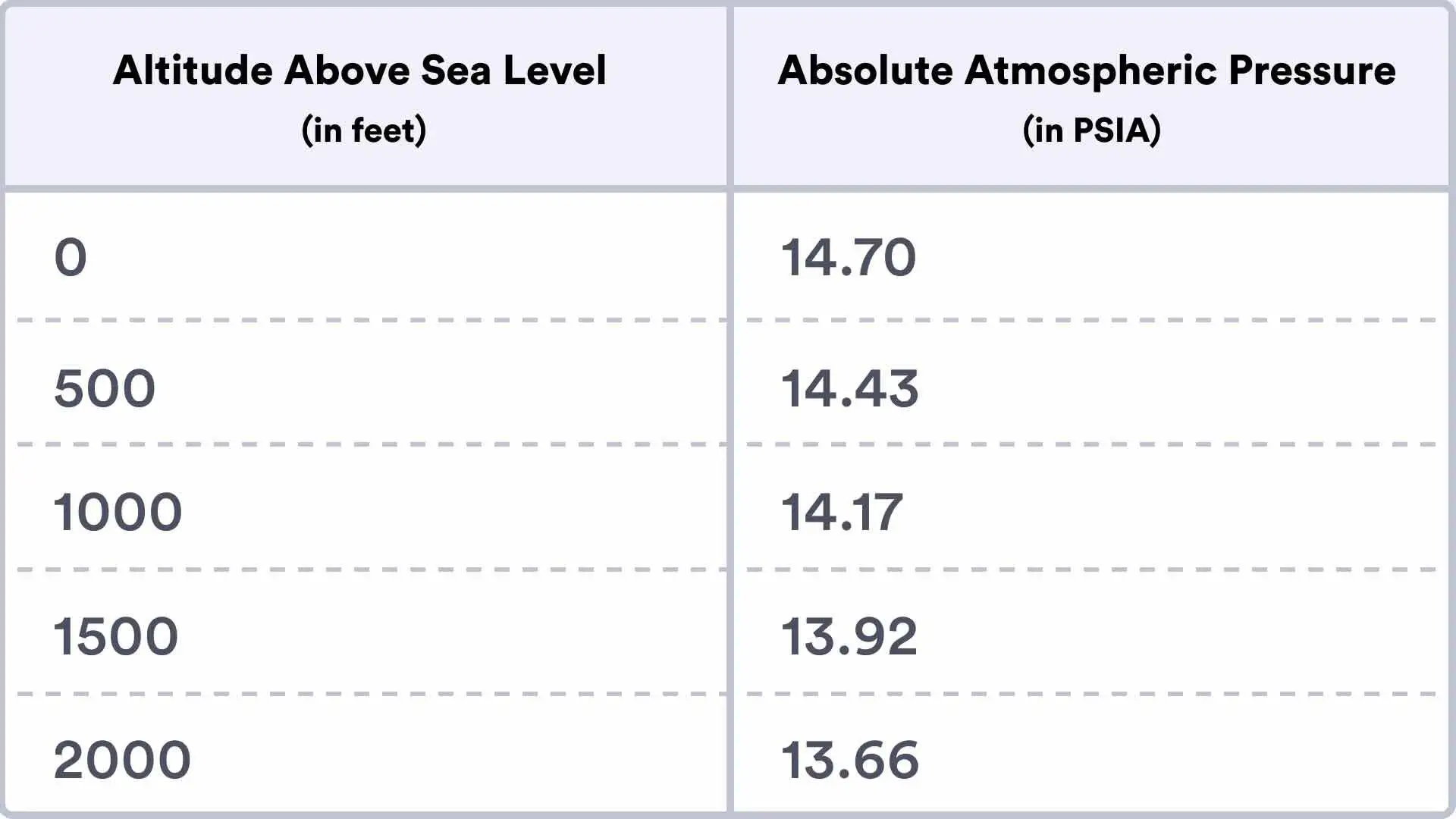

And here are the approximate atmospheric pressure values at some different altitudes:

Real-World Examples for Truckers

Now that we know and (hopefully) understand a little more about the different units for measuring pressure, let’s take a look at what that means for commercial truckers.

We used the example of tire pressure to illustrate the differences between PSI, PSIA, and PSIG. So is one more important–or more applicable–than the others?

For big rigs and other commercial vehicles, tire pressure recommendations are typically given in PSIG. Why? The short answer is because we don’t live in a vacuum (or deep space). Here on Earth, there are some real-world factors, like temperature and elevation, that can affect pressure readings.

Molecules speed up when it’s hot, and slow down when it’s cold. So the amount of force they exert will vary based on outside (weather) conditions. When we’re talking about altitude, that actually works counter to atmospheric pressure, where the higher up you go the thinner the air gets, the colder it usually is, and the more your pressure drops.

Again, the measurements will differ depending on a) how far above or below sea level you are, and b) how hot or cold your tires are when you check them.

In an air brake system, air is pressurized by a compressor. The compressed air is then pumped into a reservoir tank, where it’s stored at a specific pressure. When the brake pedal is applied, a signal is sent to the brake chamber to release the compressed air into the brake system.

Air pressure in a brake system is typically maintained around 100-120 PSIG when the vehicle is moving. This pressure level ensures that the brakes are responsive and can quickly engage when needed. If the air pressure drops below a certain level, that could mean there’s a leak in the system or a malfunctioning component, either of which could compromise the system.

Elsewhere on the vehicle, you may see some engine components use PSIA, especially when calculations require you to isolate pressure within a system. One example would be compressor mapping, and determining pressure ratio and mass flow rates to help in turbocharger selection.

In Conclusion

While the differences between PSI, PSIA, and PSIG may seem minor, it’s important to understand what each term means, what they do, and how they’re generally used in truck maintenance and repair. This distinction is especially vital when working with components, like tires and air brakes, that require precise pressure measurements.

We know it can get a little confusing, so feel free to refer back to this blog, and the handy formulas and pressure reference points we’ve provided, for a quick refresher on these concepts, or whenever the question, “What is PSIG and when do I use it?” comes up.

The bottom line is that whether you’re on the service side or a CDL driver yourself, a solid grasp of air pressure units goes a long way toward ensuring your trucks’ safety and reliability on the road.

If you are looking to start up a truck repair and maintenance shop, or are interested in upgrading your current shop, we invite you to check out Shopmonkey’s truck repair shop software. This customizable, all-in-one solution allows you to work smarter and faster while maximizing earnings and keeping your customers happy.