Most auto repair shops have two main goals–providing good service and making a solid profit. But no matter how great you and your team are at fixing cars, if the numbers don’t add up, you won’t be around long enough to strut your stuff.

One area that can make or break profitability is your auto parts markup. Too often, shops rely on outdated or overly simple pricing formulas that either leave money on the table or, worse yet, don’t even cover their costs. Others may overcorrect, marking up parts so high that they drive customers away.

The trick is finding that sweet spot–a practical middle ground between healthy profits and fair pricing. So, let’s get to work fine-tuning your markup strategy, from understanding true costs to exploring different pricing models and key factors to keep both your bottom line and your customers happy.

Understanding Your Costs

Before jumping into markups, we need to go over your costs. This isn’t just the price you pay for a part; it’s the actual cost of getting it from the supplier to your shelf and finally into the customer’s car.

Landed Cost: This refers to the total cost of acquiring a part. It includes the purchase price, shipping and handling, core charges (refundable fees paid to the manufacturer for certain parts), taxes and other applicable fees, and any special ordering fees.

Overhead Costs: These are the costs associated with running your business. They include rent or mortgage payments, utilities, employee salaries and benefits, insurance, supplies for the shop, marketing and advertising, and software and technology costs.

Calculating True Cost: To figure out your true cost, let’s use a brake caliper as an example. Say the purchase price is $50, plus $5 for shipping, another $5 for taxes and fees, and a core charge of $10 (which you’ll get back later). That means your initial landed cost is $60. Then, factor in a 15% overhead allocation to the landed cost, which adds another $9, and you’re looking at a true cost of $69 for that caliper. This is where shops can run into trouble. A 50% markup on your $50 purchase price might seem like a nice profit. But when the true cost is actually $69, that margin becomes pretty underwhelming.

Markup Strategies

Now that we know the true cost, let’s talk markup strategies. While there’s no universal approach that works for everyone, here are some of the most common ones:

Fixed Percentage Markup

The simplest approach is to mark up every part by the same percentage. So, if you decide on a 50% markup across the board, a $50 part would sell for $75, and so forth. While this method is easy to manage and keeps everything consistent, it doesn’t factor in things like part costs, type, or availability.

Tiered Markup

This system sets different markup percentages based on the type, cost, or demand for different parts. It lets you price regular items affordably while applying higher margins to specialty or hard-to-find parts. If you wanted to base it on cost, for example, parts under $10 may have a 100% markup, parts between $10 and $100 may have a 60% markup, and parts over $100 may have a 40% markup. It’s a good middle ground that keeps prices reasonable while protecting your bottom line.

Value-Based Pricing

This approach sets prices based on how much a customer perceives a part to be worth. For example, a critical safety component like a brake rotor or a performance upgrade like a high-flow muffler typically has more perceived value than a basic air filter. Most customers don’t mind paying more for parts that improve safety or performance, so you can build in higher margins. However, sometimes it’s up to you to convey that value–explaining how a part enhances safety, boosts performance, or adds longevity can help justify the price.

Competitive Analysis

This involves checking out what other local shops are charging for similar parts and services. You don’t have to mirror their prices, but it’s a good reference point to see where the market’s at. Price too high, and you might drive customers away; price too low, and you’re cutting into your profits. Just remember, every shop has different overhead costs, and some may keep parts margins low while making up for it in labor. On the other hand, if you offer better service or warranties, you’re probably OK charging a little more.

Beyond the Percentage

Pricing parts isn’t just about markups. For example, rare or hard-to-find parts can carry higher margins because customers know they can’t get them just anywhere. Offering a solid warranty or guarantee can also justify a higher markup–giving customers peace of mind while standing behind your products isn’t nothing. Client relationships matter, too. Repeat customers are the backbone of your business, and giving them discounted pricing can help keep them loyal. Plus, keeping a close eye on inventory helps refine your pricing strategy by cutting storage costs and minimizing losses from outdated parts.

The Formula for Long-Term Success

The right markup strategy for your shop starts with reviewing costs and choosing a formula that fits with your business goals, customers, and even the competition. Parts availability, their perceived value to customers, and discounts or specials for your best clients should also be considered.

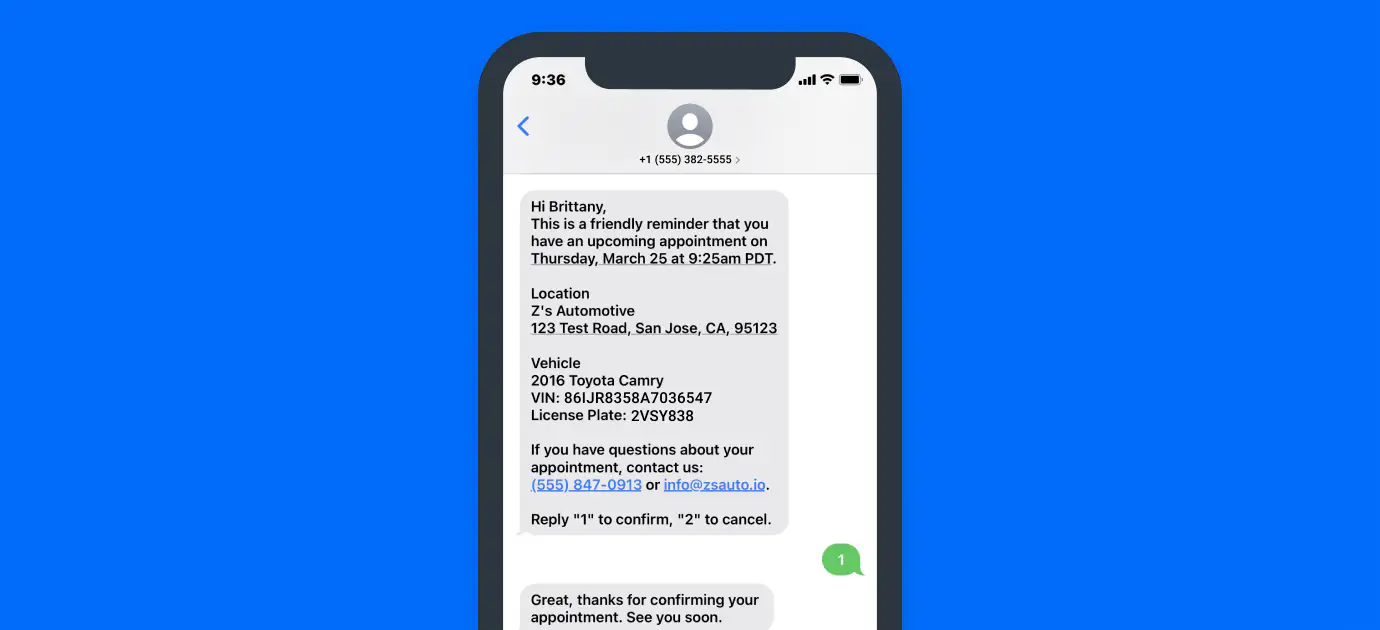

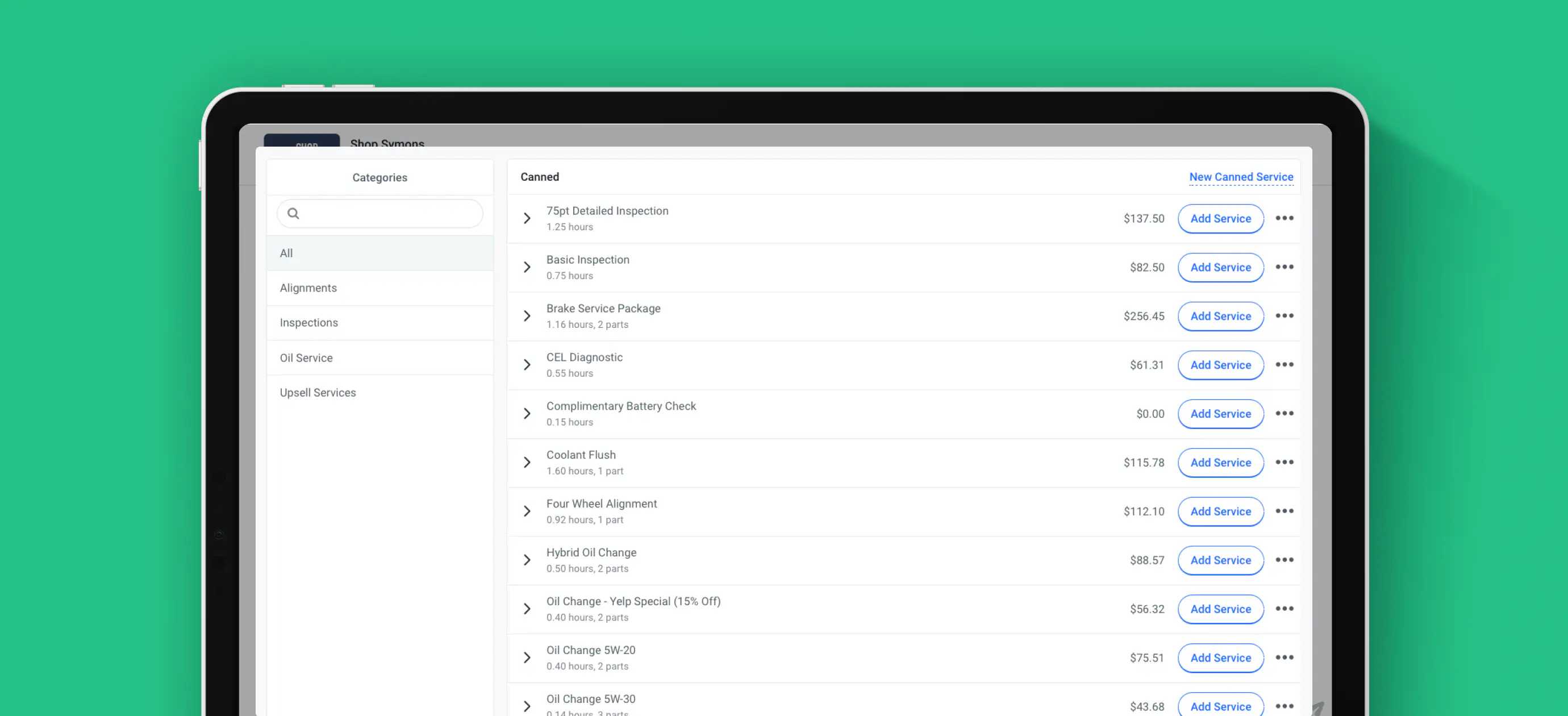

Pricing isn’t a one-and-done deal, either. You’ll need to keep close tabs on sales and costs, making adjustments along the way to maximize your profits. Some top auto repair shop management software options include tools that analyze sales and cost trends, helping you spot when your prices are too high or too low, or if they aren’t keeping up with rising parts or overhead costs.

A solid markup strategy plays a huge role in operating a well-run, profitable shop. And one of the best ways to stay on top of it is by leveraging auto parts inventory software designed to streamline pricing, track costs, and adjust margins as needed. See the difference for yourself–request a demo today!