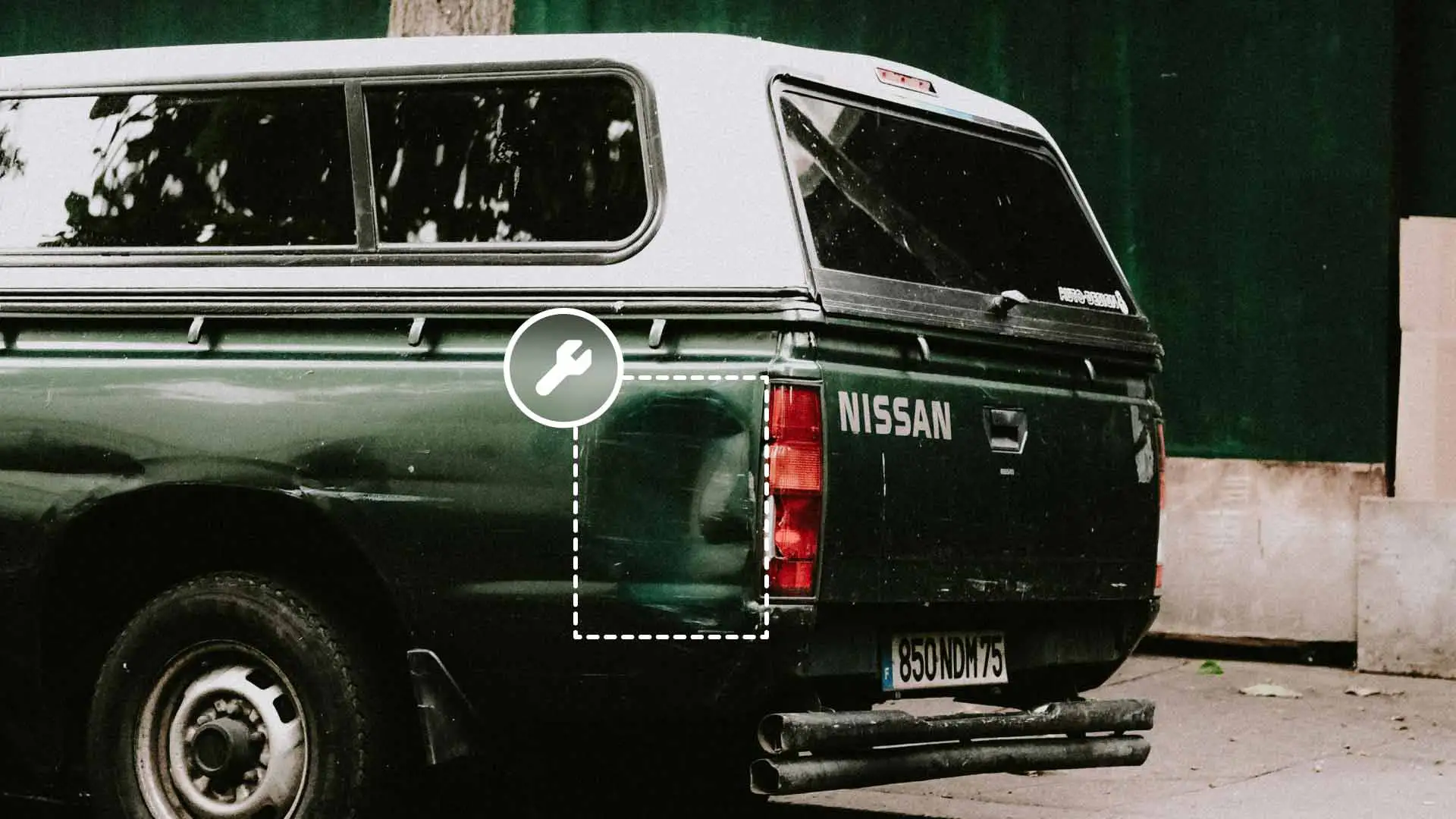

Maybe the car got too close to a shopping cart, or maybe a passing big rig kicked up loose gravel; or, it could’ve come from a sudden hailstorm. Whatever the cause, the result is more or less the same–an unsightly blemish that spoils the vehicle’s appearance.

Yes, even small dents or dings can ruin an otherwise spotless exterior. And while fixing these imperfections used to require a costly and time-consuming visit to the body shop, there’s actually an effective solution that eliminates many of the steps involved in traditional dent repair.

Paintless dent removal (PDR) is a method of carefully massaging out dents from the inside out, leaving the paint undamaged and the car or truck in like-new condition. Like any art, it takes precision, practice, and patience–as well as the right tools–to master the finer points of PDR. But for a detailing professional or ambitious DIYer, the payoff can be tremendous.

PDR Hacks

Heat & Ice Fusion: One of the most effective techniques of PDR utilizes heat and cold to manipulate metal. By applying controlled heat to a dented area, you can increase the flexibility of the paint and metal, making it easier to massage out the dent with your tools. Subsequently, applying dry ice to a heated area causes the metal to contract, helping to pop the dent out from the inside without damaging the paint. This heat and ice fusion technique is particularly useful for larger dents on bigger panels.

Light vs. Shadow: By shining lights at different angles, you can create shadows that highlight even the smallest creases and imperfections. This lets you better assess the depth and complexity of a dent and plan your approach accordingly. Investing in a high-quality light bridge or LED light, and learning how to position it to maximize the shadows, will help uncover hidden details in the metal.

Doing Dent Removal Better

Understanding Panel Complexity: The type of panel you're working with plays a huge role in determining your repair strategy. Different panels have unique curvature, stiffness, and underlying support structures that affect how the metal responds to your tools. Flat panels, like hoods and trunk lids, tend to be more rigid and less forgiving. So, you’ll want to be very careful to avoid creating additional high spots or scratches. Elsewhere, contoured panels like doors and fenders are more flexible and can usually withstand greater pressure.

Like any art, it takes precision, practice, and patience–as well as the right tools–to master the finer points of PDR.

Blind Spot Maneuvers: Dents in tight spaces–behind brace supports, along tight seams, or in heavily contoured areas–can be a real challenge…but not mission impossible. One approach involves modifying your tools to better reach into these areas. This may require bending or cutting down rods, adding specialized tips, or even making your own custom tools. Another technique involves creating access points. For this, you might have to remove some trim or molding, drill strategically placed holes, or use tabs and glue to pull the dent out from the inside.

PDR Beyond Metal

Plastic Panel Revival: Plastic bumpers and trim can be dented just like metal. Unfortunately, however, plastic is less malleable than metal and more prone to cracking, so it needs to be handled with care. The key to repairing dents in plastic is to gently apply heat to increase its flexibility. Use a heat gun or hair dryer to warm the area, then carefully massage the dent out with a plastic-specific tool. Just be careful not to apply too much pressure, as that can cause warping, discoloration, or cracking.

Hail Damage Hero: Rather than a few large dents, hail damage produces tons of small to medium-sized dents. Which means approaching these repairs requires a unique strategy. It’s often best to work in sections, systematically removing dents one by one while keeping track of your progress. You could use a mapping technique to identify and number each dent, then prioritize them based on size and location. Also, working from the top down prevents drips and drops from interfering with your repairs.

The Power of Patience

Incremental Progress: PDR requires patience above all else. Skilled technicians realize that removing a dent is not a race, but a step-by-step process of incremental progress. Rather than trying to force a dent out quickly, break it down into stages. It's about embracing the process, not rushing the outcome.

Knowing When to Walk Away: Not every dent is cut out for PDR, and pushing too hard can risk damaging the paint. If a dent is deep, has sharp edges, is particularly large, or appears in an area with thin metal, the job may be better left to a body shop. Honestly assessing your capabilities, as well as the vehicle's needs, will tell you if it’s best to walk away vs. pressing forward.

Communication is Key

Setting Customer Expectations: It’s important to set realistic expectations early on. Be upfront about the limitations of the process and the possibility that some dents may require additional body work; and explain why these dents can’t be fixed using PDR. Also, make sure you cover areas like pricing, your anticipated timeframe, and the reality that there may still be minor imperfections once the job is done.

Documenting the Process: During the repair process, document everything thoroughly. Taking detailed, high-quality photos of the dent(s) before, during, and after the repair provides a clear record of the work you performed. This allows you to both showcase your work and protect yourself in case of any disputes later on.

The Fine Art of Dent Destruction

Perfecting the art of PDR takes time, technique, practice, and patience. But with the right approach, specialized tools, and continuing education, you can absolutely become a go-to source for top-quality dent removal.

And, if you're ready to experience flawless shop management, consider a tool like Shopmonkey's all-in-one auto detailing software. With streamlined scheduling, inventory management, and customer communication tools, it's designed to help you run your shop more efficiently so you can focus on growing your business. Request a demo today and see the difference firsthand.